Designed, manufactured, tested, proven and beloved - the industry's leading reverse drive for Harley-Davidson is the easiest to use and most worry-free system. Our non-invasive reverse gear system was designed to be out of the driveline picture when going forward. We did not want superfluous reverse gear mechanisms at play spinning, jarring and/or adding additional rotational weight where 99.9% of your riding direction is spent. We did not want to compromise safety, performance, and horsepower for the tiny moments when going backward is needed.

Your metrosexual neighbor with the Honda cruiser creeps back into his garage by energizing a 2 HP electric motor. You back out of your garage by putting your bike in reverse and creeping out with the power of your proud American V-twin. Electric motors are for toys. New for this year we proudly introduce the F6R reverse kit for the 2009-Later factory Cruise Drive 6-speeds. Kit includes the door, side cover, countershaft, reverse gears and shift system, safety solenoid and related hardware. The F6R kit adds a reverse gear to any existing 2006-later factory big twin 6 speed. The system is unlike any other on the market – it works off the stock shift lever. With a simple switch housing and a kick of the shift lever you’re in reverse. It’s that simple. No reaching near hot pipes to put your bike in reverse by hand. With the BAKER reverse system, you’ll be able to safely shift from 1st to reverse and back with no risk of engaging both gears at once. You’ll also find it’s much easier to find neutral than on a stock bike. Our reverse gears are fully heat treated, with diamond ground tooth profiles and cut from gear grade 8620 steel. Our gear ratios were chosen to make it easy for you to maneuver your bike in reverse. The overall 4.98:1 gear ratio in reverse is essentially a creeper gear, which is 45% shorter than the stock 3.34:1 first gear.

The F6R kit comes standard with a black switch housing.

- Adds a reverse gear to the stock Cruise Drive 6-speed Transmission

- A full complement of parts and detailed instructions included for an easy installation

- The reverse is designed as a creeper gear for the safest operation possible

- Reverse selection controlled by foot shift lever. Shift into reverse like any other gear. (R-1-N-2-3-4-5-6 Shift Pattern)

- Redundant spring system on the safety lever assembly make it is the safest reverse system on the market today

- Included shift drum improves shift quality and the ability to find neutral, every time

- True ‘plug & play’ wiring harness. No using the starter motor for reverse maneuvers either

- The F6R kit comes standard with a black switch housing

- Backed by a 2-year limited warranty

Benefits

- Strong, true reverse transmission

- No case modifications required for reverse gearset installation

- No reaching near hot pipes or auxiliary levers to work

- Any existing 2006-2020 factory Big Twin 6-speed*

*Will NOT fit M8 Softail applications.

*For Dyna applications call us for more information- 224-475-3633

Actuator:

- 2007-08 Touring Model Exhaust Installation Notes: The stock exhaust will clear the F6R front facing solenoid side cover and solenoid. An exhaust that follows the path of stock exhaust or true duals where the rear pipe travels directly to the left side of the motorcycle over the top of the transmission will work. Two-into-one style pipes where the rear head pipe goes down the front of the stock transmission side cover require the use of the rear facing solenoid side cover.

- 2009-Later Touring Model Exhaust Installation Notes: The stock exhaust two-into-one-into-two design requires the use of the rear facing solenoid side covers.

2013 Big Twin Hydraulic Clutch Kit:

- Customers installing a BAKER F6R on Screamin Eagle bikes with factory installed hydraulic side covers will need to purchase the 2013 hydraulic clutch kit. This kit includes one center push rod (PN 37090-98A), one screw adjuster (PN 37092-06), one release plate (PN 37903-90), one internal retaining ring (PN 37909-90), and one jam nut (PN 7848W). These parts retro-fit the clutch rod and adjustment to a mechanical ball and ramp. The side cover is set-up to work with the BAKER 1.5” piston and push rod in the F6R side cover.

- 4.98:1 ratio reverse gear in the F6R gearset, which is 45% shorter than the stock 1st gear ( 3.34:1). Making it essentially a creeper gear

- Reverse gears and dogs made of 8620 gear steel, fully case hardened to 58-62 Rockwell C. Ground tooth profiles with diamond coating tooling

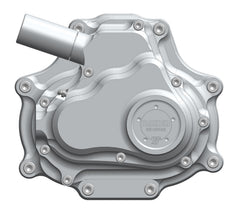

- Billet (6061-T6) Aluminum bearing door and side covers. Available in polished finish.

- Preheat treated 4140 billet steel shift fork (28-32 Rockwell C) rides on a case hardened, ground finish fork rod

- Hydraulic side cover (1.5″ Piston) works with stock and aftermarket 11/16″ bore hydraulic clutch lever assemblies

- All included bolts are polished stainless steel

- Included shift drum is machined from 12L14 billet steel, then case hardened to 48-52 Rockwell C (R-1-N-2-3-4-5-6 Shift Pattern)

- Adds a reverse gear to the stock Cruise Drive 6 Speed Transmission

- Typical install time is 6-9 hours depending on the model of motorcycle, exhaust, and installed accessories

|

F6R, Safety Solenoid ‘Off’, Reverse Locked Out

|

F6R Safety Lever, At Rest

|

F6R In Reverse Gear

|

|

F6R In Reverse, Moving Parts

|

Reverse Kits

| New PN |

Old PN |

Description |

Fitment |

| F6R-MP02 |

F6RV-MP |

F6R Kit, Cable Style, Front Solenoid, Polished |

06-Later Dyna, 07-Later Softail,07-08 Touring* |

| F6R-MR02 |

F6RV-MCR |

F6R Kit, Cable Style, Rear Solenoid, Polished |

2009-Later Touring* |

| F6R-HF02 |

F6RV-HC |

F6R Kit, Hydraulic, Front Solenoid, Polished |

06-Later Dyna, 07-Later Softail,07-08 Touring* |

| F6R-HF02 |

F6RV-HP |

F6R Kit, Hydraulic, Front Solenoid, Polished |

06-Later Dyna, 07-Later Softail,07-08 Touring* |

| F6R-HR02 |

F6RV-HCR |

F6R Kit, Hydraulic, Rear Solenoid, Polished |

2009-Later Touring* |

F6R Kits Notes:

Front or Rear Facing Solenoid Version F6R Kits Contain The Same Parts Except For The Shift Drum, Safety Lever And Side Cover. There Is A Rear & Forward Solenoid Version Of Each Part.

*2007-08 Touring Model Exhaust Installation Notes: Stock Exhaust will clear the F6R front facing solenoid side cover and solenoid. Exhaust that follows the path of stock exhaust or true duals where the rear pipe travels directly to the left side of the motorcycle over the top of the transmission will work. 2 INTO 1 STYLE PIPES WHERE THE REAR HEAD PIPE GOES DOWN THE FRONT SIDE OF THE STOCK TRANSMISSION SIDE COVER REQUIRE THE USE OF THE REAR-FACING SOLENOID SIDE COVER. See the ‘F6R Side Cover Styles’ images further down the page for solenoid locations.

*2009-Later Touring Model Exhaust Installation Notes: The Stock exhaust 2 into 1 into 2 design requires the use of the Rear Facing Solenoid Side Covers. See the ‘F6R Side Cover Styles’ images further down the page for solenoid locations.

Here is a list of known to fit aftermarket exhaust pipes that clear the F6R system with images below:

- Rinehart True Duals, 2009-12 Touring Models: Click Here

- Samson True Duals, 2009-12 Touring Models: Click Here

- Bassani True Duals, 2009-12 Touring Models: Click Here

|

Samson True Duals, 2009-12 Models

|

Bassani True Duals, 2009-12 Models

|

|

Rinehart True Duals, 2009-12 Models

|

|

F6R Side Cover Styles

|

F6R Cable Style Front Facing Solenoid, Side Cover Assembly

|

F6R Hydraulic Front Facing Solenoid, Side Cover Assembly

|

|

F6R Cable Style Rear Facing Solenoid, Side Cover Assembly

|

F6R Hydraulic Rear Facing Solenoid, Side Cover Assembly

|

*Does not fit on 2015 handlebars.

FERRULE STYLE CLUTCH CABLE TECH TIP:

This tip applies to F5R, F6R, F5K, F6K, RSD and Big Dog style clutch cable installations that utilize a split ferrule for cable retention. It is recommended that the inner cable, ferrule and ball ramps are coated liberally with wheel bearing grease upon final installation. This step has been omitted for photo clarity.

After attaching the clutch cable to the clutch lever, be sure that the cable adjuster is fully collapsed. Screw the cable into the side cover. Slide the ball ramp over the exposed inner cable, then the split ferrule over the inner cable end. Rotate the ball ramp fully rearward removing all of the slack from the inner cable and engaging the ferrule into the ball ramp. Install a miniature nylon cable tie on the inner wire directly in FRONT of the ball ramp as far back as possible. Snip the excess tie as short as possible. This will prevent the ferrule from accidentally becoming dislodged during installation and/or clutch adjustment.

Recommended Fluid Level

Picking the right transmission fluid ensures the life and durability of your transmission, that’s why BAKER recommends a fully synthetic GL-5 rated gear weight oil of 75W-140. If a GL-5 rated gear lube is not available, these commonly carried viscosities (weights) will work 75W-90, 75W-140 and 85W-140. BAKER does not recommend the use of Syn3 (20W-50). For Bert’s article on ‘Oil & Spiders’ Click Here

- BAKER F6R Fluid Capacity Dry: 30-32fl-oz

- BAKER F6R Fluid Capacity Wet: 26-28fl-oz

Installation Instructions

- BAKER F6R Installation Instructions with Exploded Views New Safety Lever: Click Here

- BAKER F6R Installation Article By Rogue On Bikernet: Click Here

Final Look

Final Look